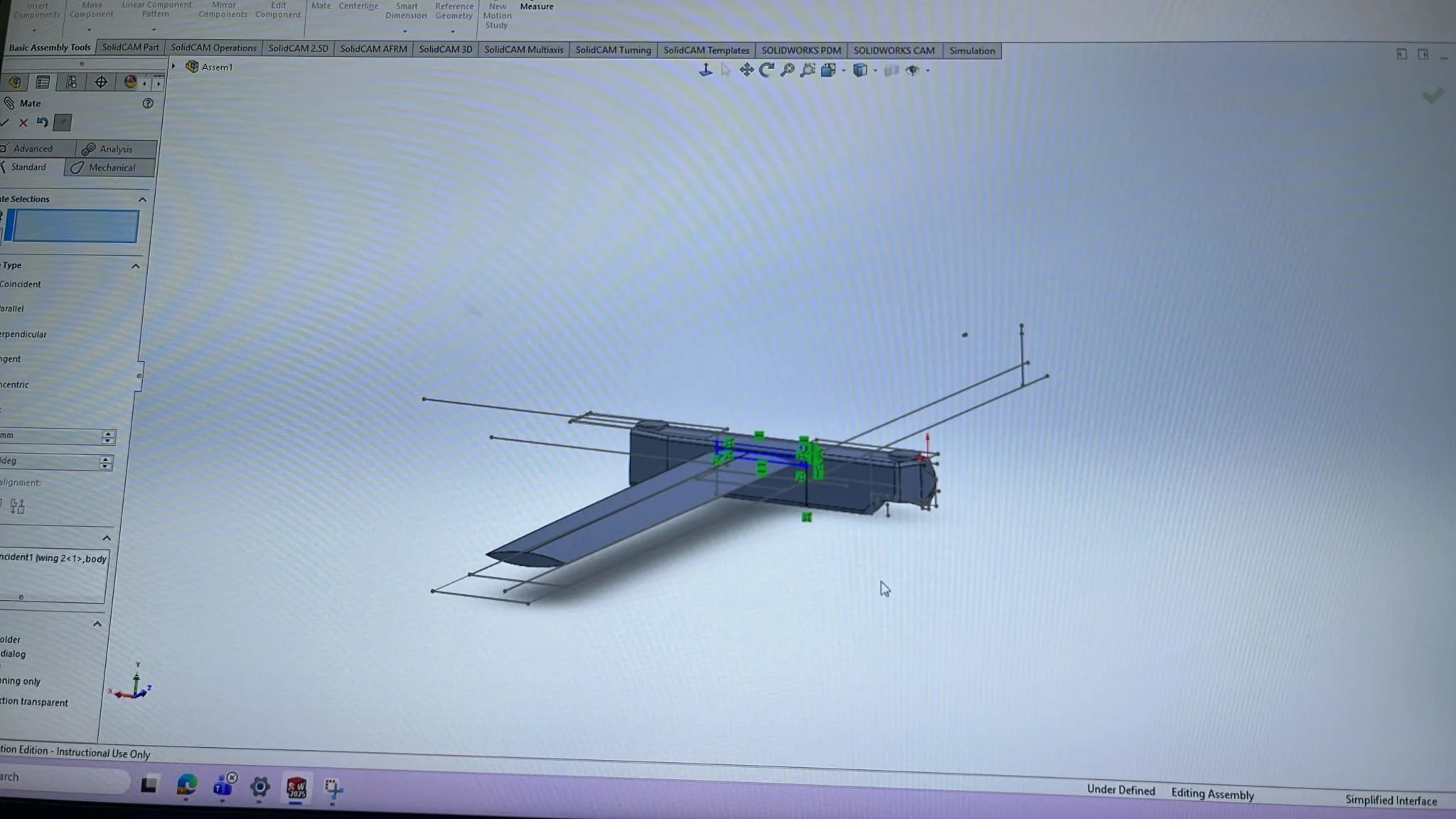

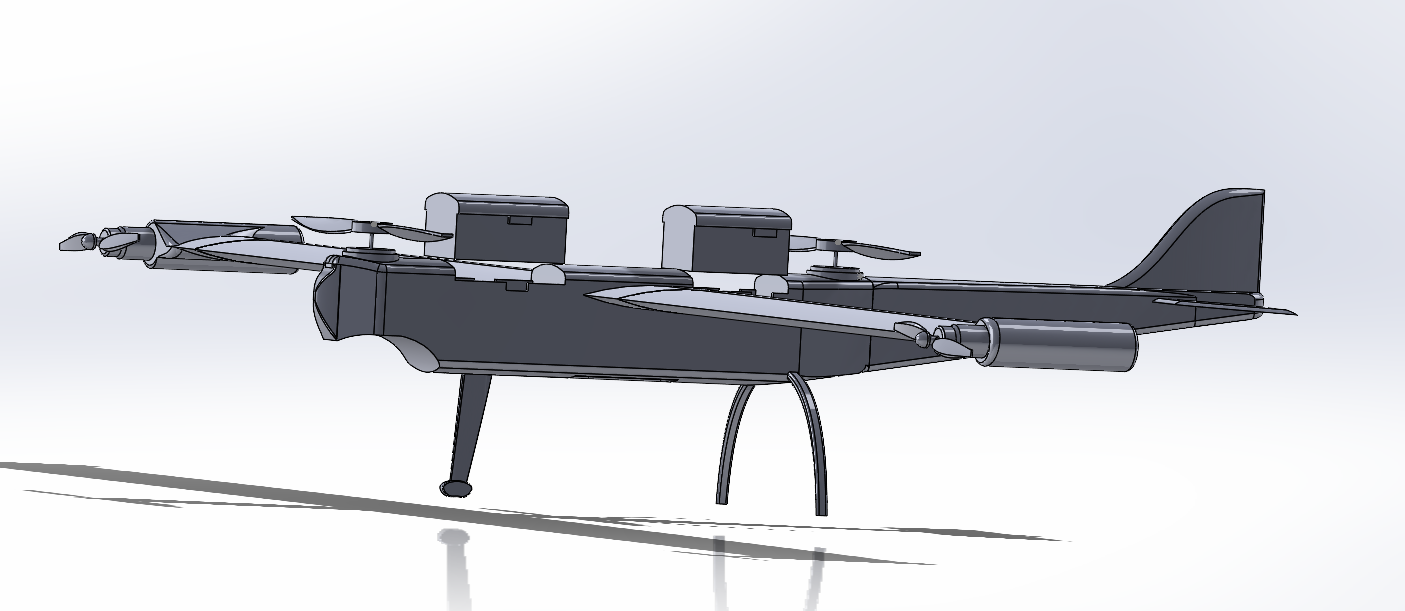

The design process for this VTOL (Vertical Take-Off and Landing) UAV began with a clear source of inspiration: the highly efficient Autel Dragonfish Pro. Aiming to replicate its versatile flight capabilities, I utilized SolidWorks to engineer a hybrid airframe that combines the vertical lift of a multirotor with the cruising efficiency of a fixed-wing aircraft. The modeling process started with the fuselage, where I created a rough skeletal frame using base sketches to define the overall geometry. From there, I utilized extrusion features to build the substantial basis of the wings and the body, establishing the aerodynamic profile before focusing on the internal and external hardware complexities.

Once the primary airframe was established, I incorporated the mechanical and functional details. The propulsion system features a distinct configuration comprising two fixed lift propellers mounted on the main body and a tilting propeller mechanism on each wingtip to facilitate the transition between hover and forward flight. I modeled these propeller assemblies in three specific components: the central shaft, the propeller blade, and the aerodynamic spinner . This modular approach allowed for a realistic representation of the moving parts required for the VTOL functionality.

Internally, the fuselage was engineered to prioritize weight distribution and component protection. I carved out three dedicated compartments within the body to house the essential avionics and power systems. These sections were specifically dimensioned to contain the battery unit, the navigation stack—including the IMU, barometer, compass, RTK, and positioning system—as well as the flight controller and the fault warning and communication monitoring systems. This layout ensures that sensitive electronics are shielded while maintaining a center of gravity optimal for flight stability.

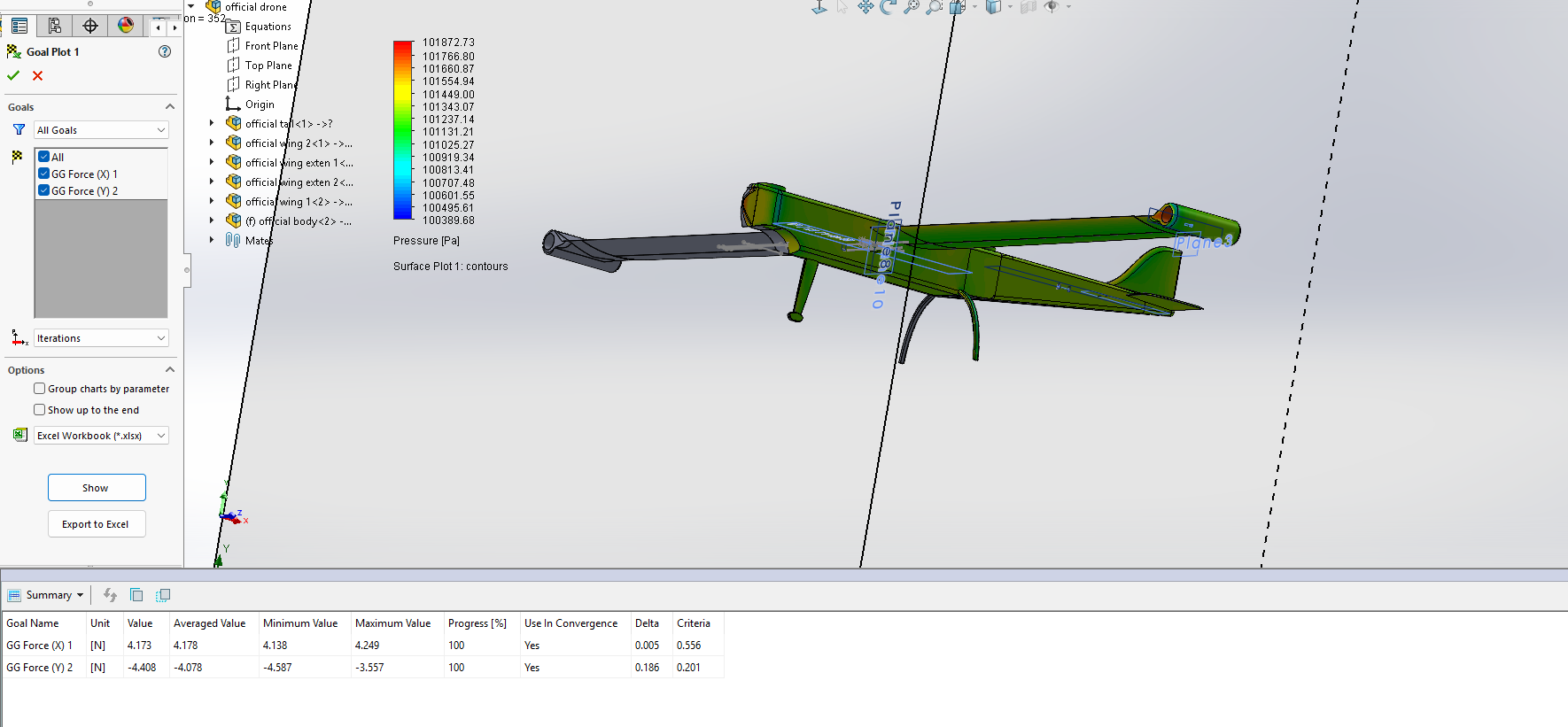

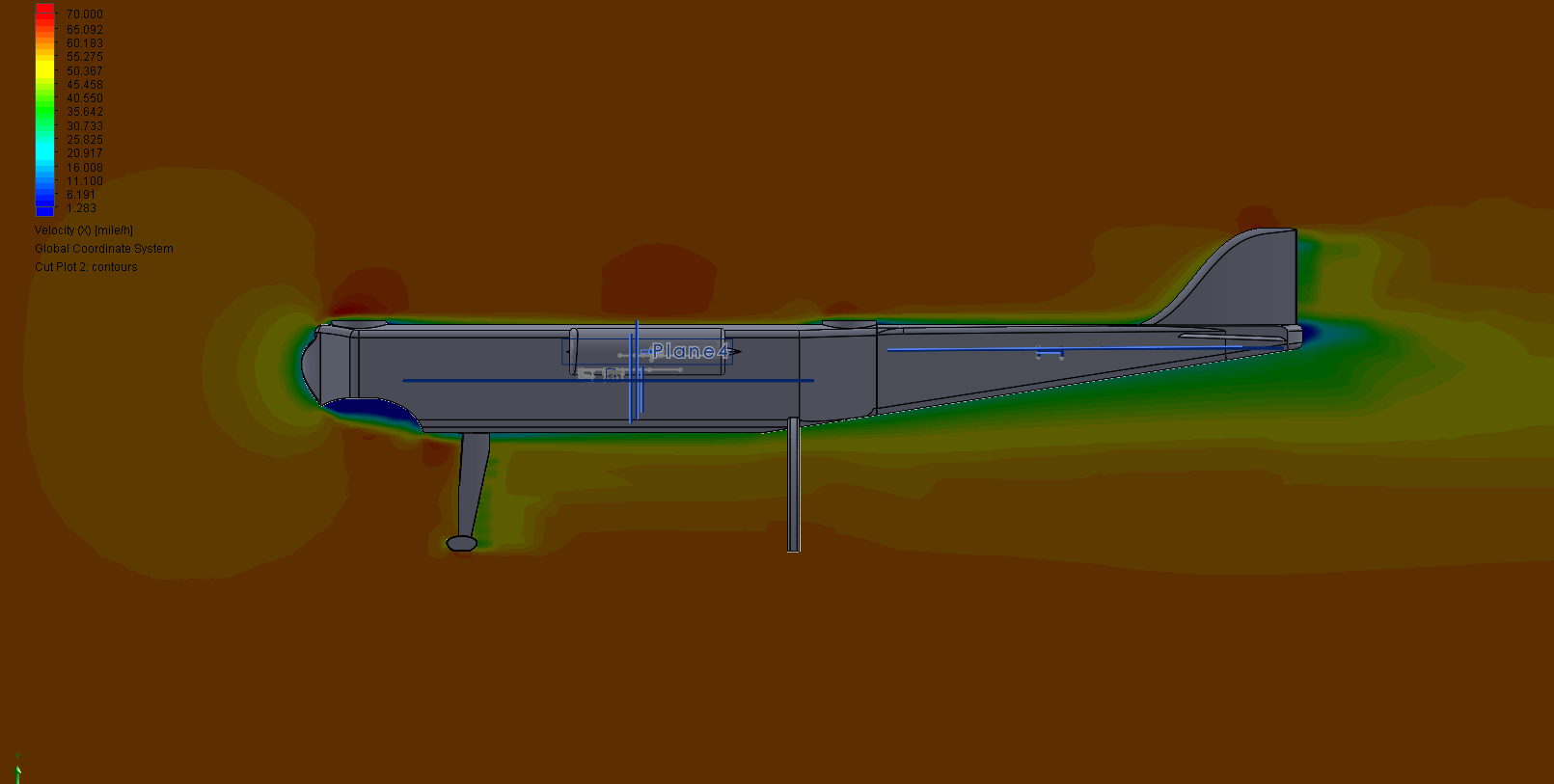

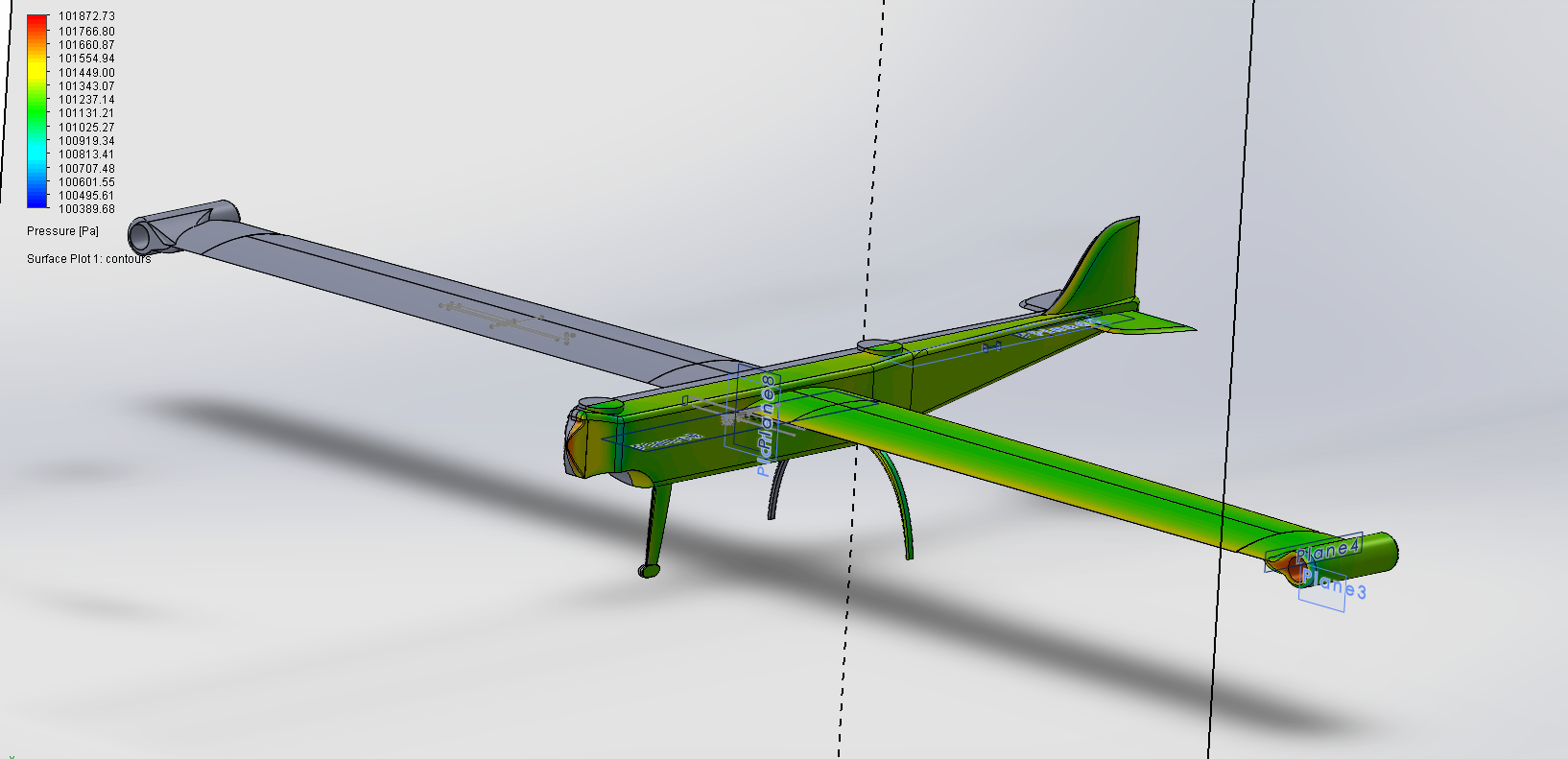

To validate the aerodynamic performance of the design, I conducted a Computational Fluid Dynamics (CFD) analysis using SolidWorks Flow Simulation. The study focused on an external flow analysis over the side profile of the drone to visualize how air interacts with the fuselage and wing structures. The resulting velocity cut plots display the airflow distribution, highlighting areas of high velocity (indicated in red/orange) over the airfoils and lower velocity wakes behind the body. This visualization was crucial for identifying high-pressure zones and ensuring the streamlined shape effectively minimizes drag during forward cruising.

Upon running the computational fluid dynamics simulation, I obtained concrete quantitative data that validated the airframe's efficiency. The goal plots indicated a stable convergence after roughly 130 iterations, yielding a global drag force of 4.17 N against a lift magnitude of 4.08 N, which confirms that the wing geometry generates sufficient lift to support the internal payload. Analyzing the surface pressure distribution, I observed the expected high-pressure stagnation zones in red along the nose and leading edges, which transitioned smoothly into lower-pressure gradients across the fuselage. The velocity cut plots and streamline trajectories further illustrated this aerodynamic behavior; I could clearly see air accelerating to peaks between 60 and 70 mph over the upper surfaces to generate lift, while a distinct low-velocity blue wake trailing the aft fuselage highlighted a specific area of induced drag that, while manageable, points to a clear opportunity for future optimization to maximize flight endurance.

By leveraging SolidWorks for both complex mechanical modeling and rigorous CFD analysis, I successfully engineered a Dragonfish-inspired hybrid VTOL UAV that balances a protective internal layout for sensitive avionics with a verified aerodynamic profile capable of efficient cruising and stability.

FRAME CREATION & PRESSURE SIMULATION

PROPELLER ANALYSIS

THROTTLE TILT

UAV Engineering & Design

WING ANALYSIS

IOT Simulation

AIoT & Automation

OCELEX Route Optimisation Application

Conveyor

ANALYSIS

AI TRAINING

Workings

EQUATIONS OF MOTION AND CONTROL

CMEMS Data