CISCO PACKET TRACER

To validate the architecture of this fleet, I utilized Cisco Packet Tracer as my simulation engine. I chose this specific software because the viability of this mission relies entirely on flawless wireless communication, not just physical mechanics. Packet Tracer provided the ability to model the invisible data streams between the UAV and the mothership, allowing me to prototype and troubleshoot the complex IoT decision-making logic in a risk-free virtual environment before any physical hardware is ever deployed.

To achieve this, I engineered the system logic using a central server as the brain of the operation. I configured a Motion Detector to simulate the drone's AI vision; when it detects a plastic hotspot, it instantly transmits data to the server. The server then processes this input using conditional logic I defined: if plastic is confirmed, it automatically commands the support boats (represented by sirens) to deploy their collection nets and unlocks the ship's intake conveyors.

I also realized that for this system to be viable in the real world, it needed self-preservation instincts. I integrated a "Trip Sensor" to simulate a sea-state monitor that constantly checks for storms or rough waves. If this sensor trips, it activates a safety override I programmed into the server. This logic acts as an immediate "kill switch," forcing the cargo bay doors to lock and the nets to retract to prevent catastrophic damage to the equipment, overriding any collection commands.

This screen proves that the UAV is successfully connected to the Fleet's wireless network.

This represents the Network Infrastructure Management. Instead of manually programming every single drone or boat, I configured the Mothership to dynamically assign addresses to any new device that enters the network.

Real Time

This level of automation is necessary because manual ocean cleanup is inefficient, costly, and hazardous for crews. By simulating this architecture, I intended to prove that we can optimize collection routes and react to changing environmental conditions faster than a human captain could. This project serves as a proof-of-concept for how scalable IoT technology can turn a chaotic environmental crisis into a automated logistical operation.

Simulation

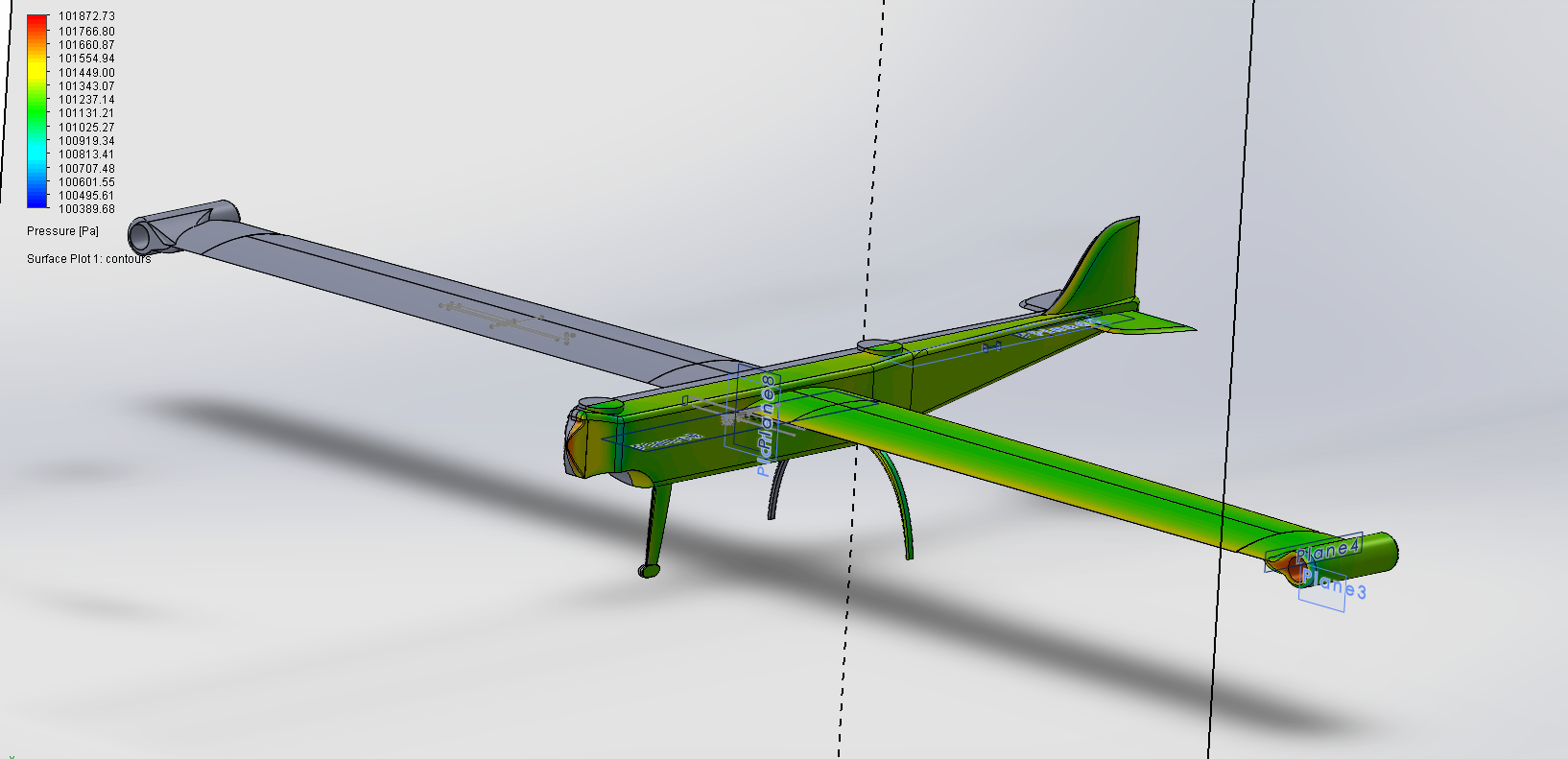

FRAME CREATION & PRESSURE SIMULATION

PROPELLER ANALYSIS

THROTTLE TILT

UAV Engineering & Design

WING ANALYSIS

IOT Simulation

AIoT & Automation

OCELEX Route Optimisation Application

Conveyor

ANALYSIS

AI TRAINING

Workings

EQUATIONS OF MOTION AND CONTROL

CMEMS Data