Download.

CAD

SOLIDWORKS®

SolidWorks Part

STL

Quantity:

2

Dimensions:

101 X 73 X 50.5mm

Quantity:

1

Dimensions:

106 x 104 x 79 mm

Quantity:

1

Dimensions:

52 X 44 X 42mm

Quantity:

2

Dimensions:

11 x 9.4 x 5mm

Quantity:

2

Dimensions:

20 x 4mm

Quantity:

2

Dimensions:

15.5 X 13.4 X 12mm

Quantity:

2

Dimensions:

200 x 25.4 x 25mm

Quantity:

2

Dimensions:

60 x 30 x 10mm

Quantity:

2

Dimensions:

10 x 4mm

The Process.

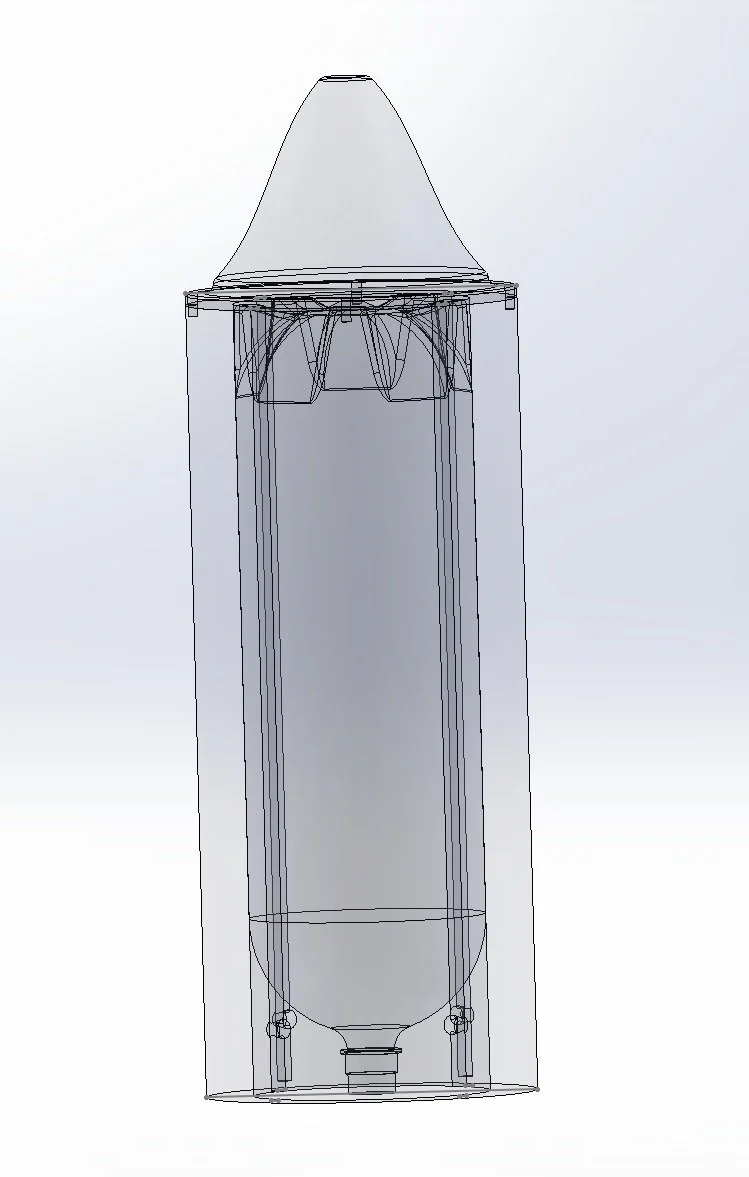

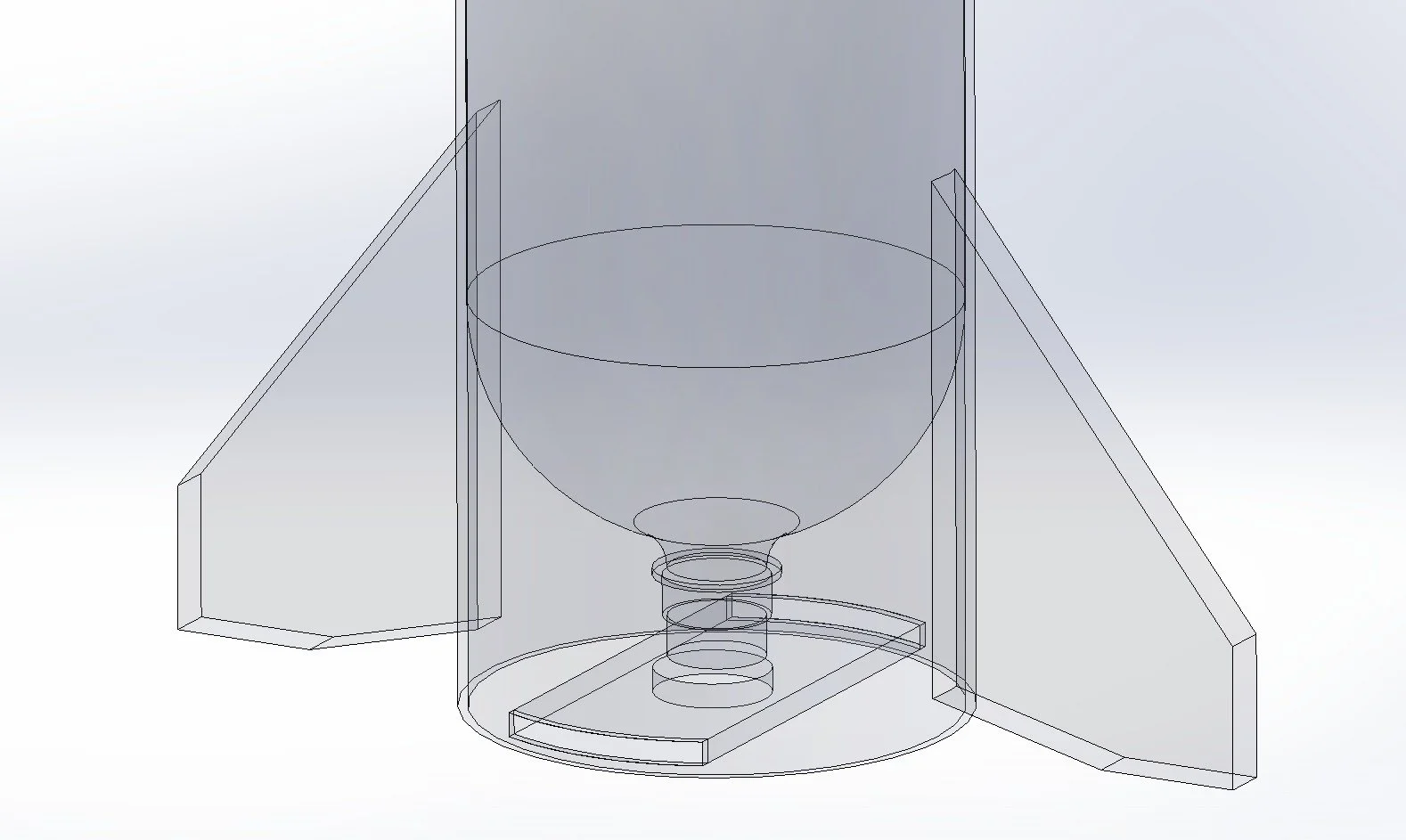

I began by designing a cone secured with screws inside a sturdy casing, using strings to hold the bottle in place.

I later cut the cone in half to create a parachute mechanism, replaced the screws with strings, and added upper fins for stability. The strings were secured underneath with tape.

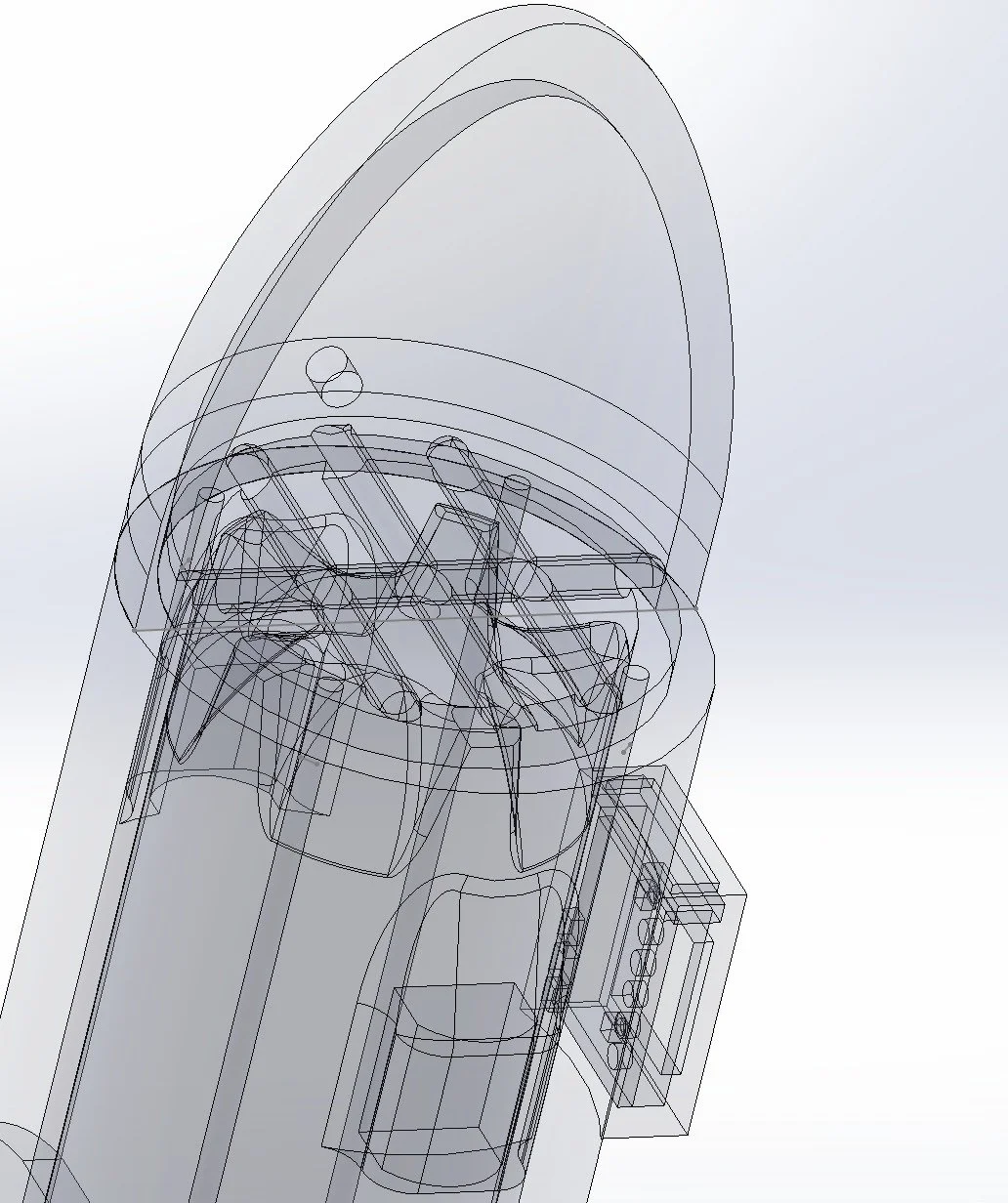

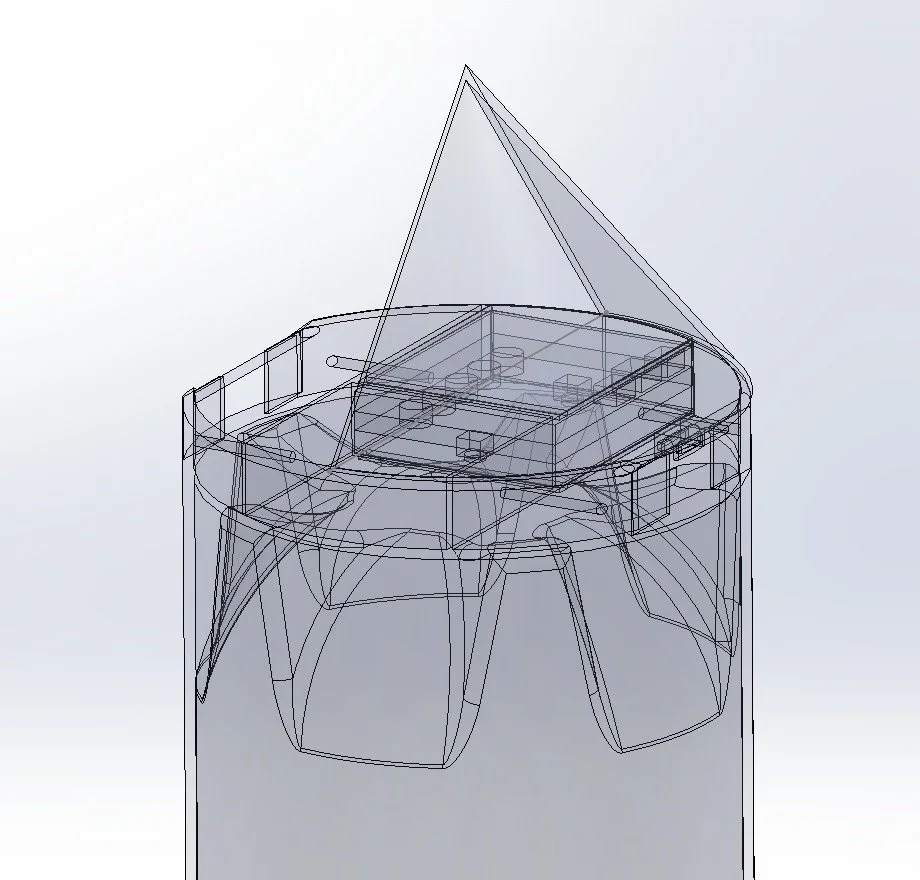

For the Micro:bit, I incorporated a side-mounted SD slot, a cylindrical frame to support the parachute, and aerodynamic fins for added stability.

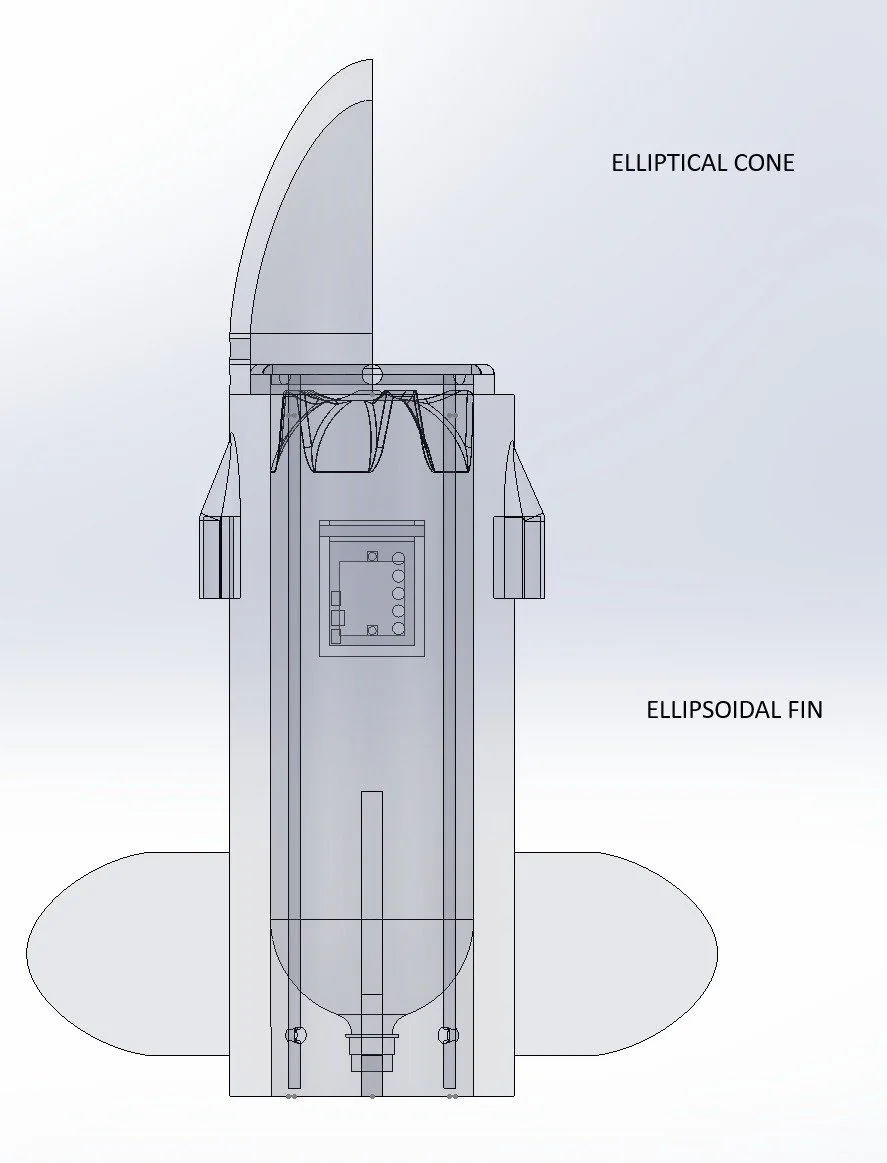

After researching fin designs, I shortlisted delta, elliptical, and clipped tapered swept fins. I chose the clipped tapered swept fin for its low drag, good stability, and ease of construction. Delta fins were bulkier with higher drag, while elliptical fins lacked structural strength and were harder to produce.

For the nose cone, I considered tangent ogive, elliptical, and conic shapes. I selected the conic design due to its simplicity, strength, and better performance at high speeds, compared to the more complex ogive and elliptical shapes.

I redesigned the model to be 90% lighter.

I moved the SD slot from the side to inside the cone to improve aerodynamics, which required reworking the internal layout.

This also led to a redesign of the parachute string posts, making them thicker to prevent snapping.

Additionally, I replaced the string system with a pivot hinge for the cone and added a sliding lock to secure the bottle.

After submitting the design, the printer technician estimated a 70-hour print time due to the casing. To address this, I reduced the casing by 80% and increased the size of the support cylinders to save time and material.

I added landing gear to the tapered fins and designed it to deploy when the nose cone falls off by making the cone clip into a rotating mechanism that triggers the landing gear to extend upon impact.